STATIC OUTPUT

Pressure function

Altitude function

- ± 2 ft. @ 0 ft.

- ± 6 ft. @ 35,000 ft.

- ± 12 ft. @ 50,000 ft.

Climb function

DIFFERENTIAL OUTPUT (REFERENCED TO STATIC)

Secondary Static or Pitot Output

Power Requirement

External Interfaces

Dimensions & weights

Environmental Specs

PITOT OUTPUT

Pressure Function

Airspeed Function

- ± 0.5 knots @ 50 knots

- ± 0.25 knots @ 100 knots

- ± 0.05 knots @ 650 knots

Mach Function

Three Outputs

In addition to the Primary Static and Pitot outputs, a third output is provided. This output can be used as a secondary static, a differential static or secondary pitot. This output allows the user to create a second altitude (in feet or mtrs), a second absolute pressure (in inHg or mbar), a differential pressure for simulating AOA (in Diff.inHg or Diff mbar) or a differential pressure for generating a second airspeed (in knots or kmph) to simulate AOS. When the third output is not used, the tester operates exactly like our 2-output tester (Model 6300)

RVSM compliant

The high accuracy of the tester and NIST-traceable calibration make the tester fully RVSM-compliant and suitable for use on all RVSM-compliant aircraft.

Calibration period

1 year

Automated operation

Simply enter the target set-points for the three outputs and the unit automatically achieves the targets, ramping at the programmed rates. Control at the set-point is stable within ± 1 foot, ± 0.1 knot or ± 0.001 inHg

Programmable limits

User-programmable limits for altitude, airspeed, differential pressure, Mach and VSI provide protection to the aircraft.

“Jog” and “Hold” features

Set-points can be “jogged” up or down in small increments. Ramping to a set-point can be put on “hold” and controlled at the current measured value.

“Ground” feature

Brings Pitot and Static outputs to ambient “ground” pressure after completing a test.

“Profiles” feature

A profile of set-points can be downloaded from a PC, allowing the user to step through the set-points using a single key. Each profile can have up to 50 set-points and 12 profiles can be stored in the unit.

Leak checks

Leak-checks can be performed independently on any of the three outputs. The display of “instant” leak rates provides immediate feedback to the user.

Pressure & Vacuum source

Built-in high-capacity dual vacuum pumps and pressure pump provide the pressure and vacuum source for the unit.

Remote unit

The Remote unit is the operator interface for the tester. All valid parameters of all three outputs are clearly displayed simultaneously on a single screen on the remote.

Manual Vent

The tester includes precision metering valves to enable manual venting of all three outputs, in the event of power-loss

APPLICATIONS

Ideal tester for use with aircraft equipped with SmartProbe™ that have the ability to sense AOA and/ or AOS.

Leak-checks and Air-data-system accuracy-checks on all RVSM aircraft including aircraft with SmartProbe™. The tester can be used either in 3-output mode or 2-output mode. In 2-output mode this tester operates exactly like our Model 6300.

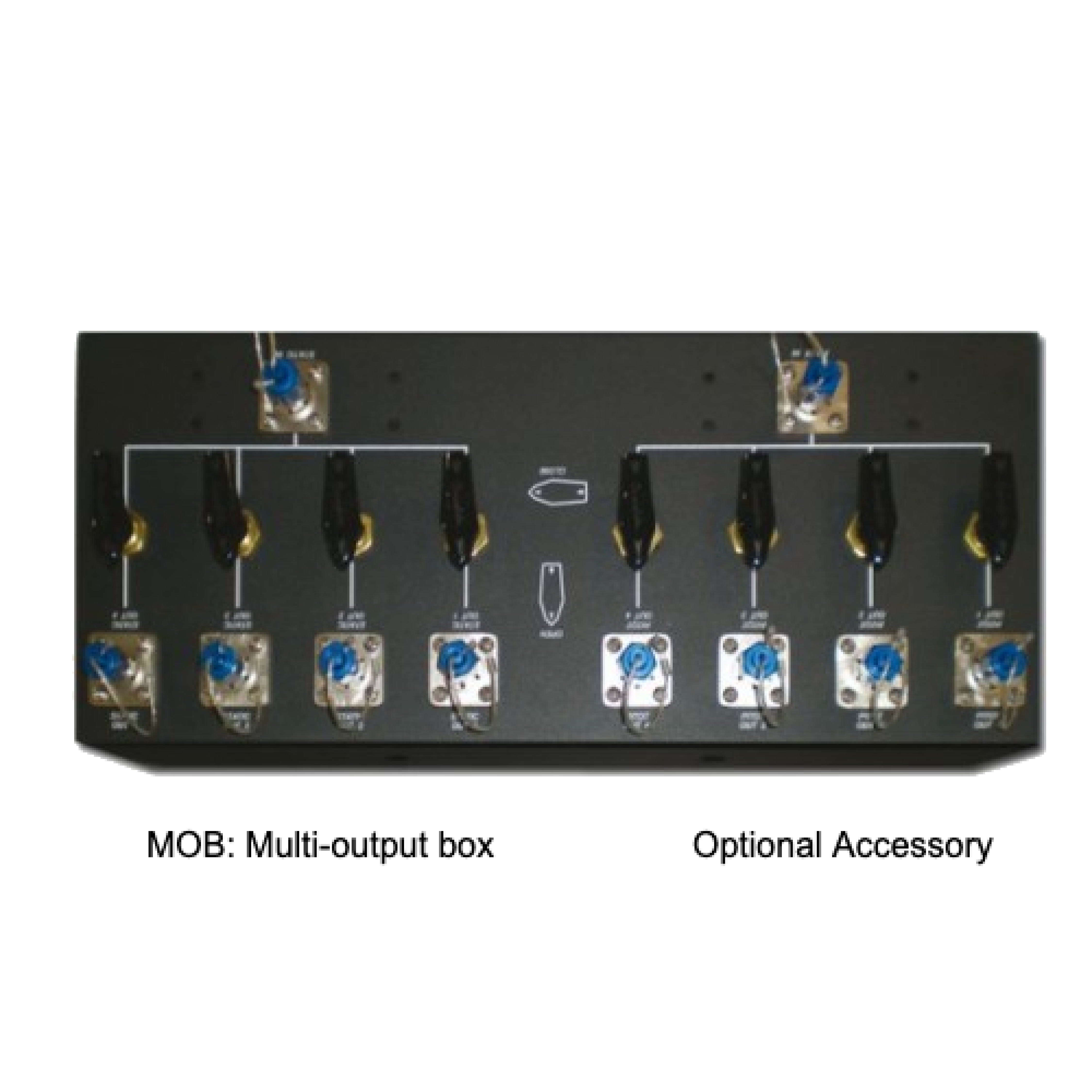

When the 6600 is used with the OSM (Output Switching Module) it is possible to completely automate leak checks, which can be performed either individually on each port of the aircraft probes, or simultaneously on all ports. Using the OSM makes it easy to isolate leaks and connection of the hoses and adapters to the aircraft is greatly simplified.